FABRICATION

CONCEPTUAL FABRICATION

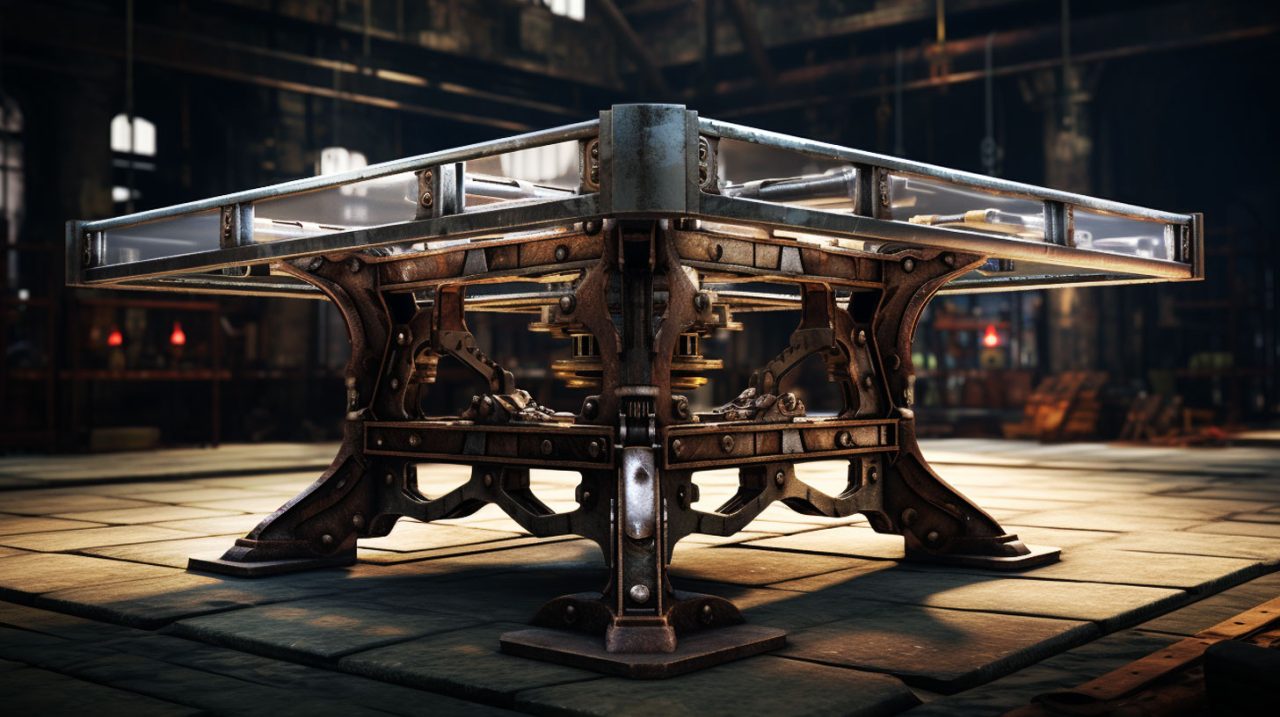

Concept Development And Fabrication For Full Scale Structural Prototypes..

METHODOLOGY

Every project follows a defined path from concept to fabrication. Scope, site conditions, and constraints are established early. CAD development translates ideas into buildable systems. Prototypes and mockups reduce unknowns before production. Fabrication follows documented steps with checkpoints at each stage. Tolerances, finishes, and installation requirements are controlled throughout. The outcome is a finished piece that performs exactly as intended.

PROCESS CONTROL

Every project is governed by documented scope, site constraints, and fabrication controls. Scope, site conditions, and constraints are established early. CAD development translates ideas into buildable systems. Prototypes and mockups reduce unknowns before production. Fabrication follows documented steps with checkpoints at each stage. Tolerances, finishes, and installation requirements are controlled throughout. The outcome is a finished piece that performs exactly as intended.