CAPABILITIES

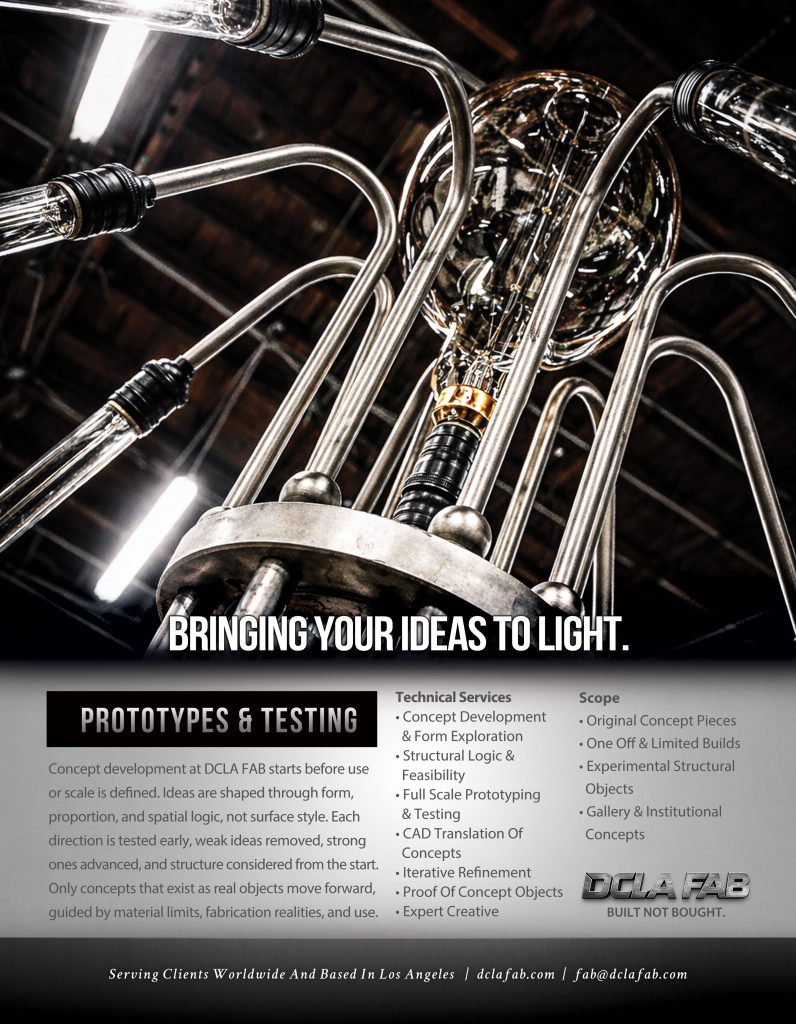

PROTOTYPING AND TESTING

Concept Validation, Structural Proofing, And Real World Fabrication Testing.

METHODOLOGY

We develop prototypes as working test objects, not presentation models. Each prototype is built to expose structural limits, material behavior, and assembly constraints early in the process. This allows de sign decisions to be validated against real loads, tolerances, and fabrication methods before cost and complexity increase. Failures are expected and used as data. The goal is to remove uncertainty and confirm feasibility before fabrication begins.

PROCESS & CONTROL

Each project follows a defined process from scope through final validation. Design assumptions are documented, reviewed, and tested before fabrication starts. CAD layouts, mockups, and prototypes are used to control risk and reduce unknowns. Tolerances, schedules, and installation requirements are tracked end to end. This ensures fabrication proceeds with clear intent and predictable outcomes.