CAPABILITIES

FABRICATING AND MACHINING

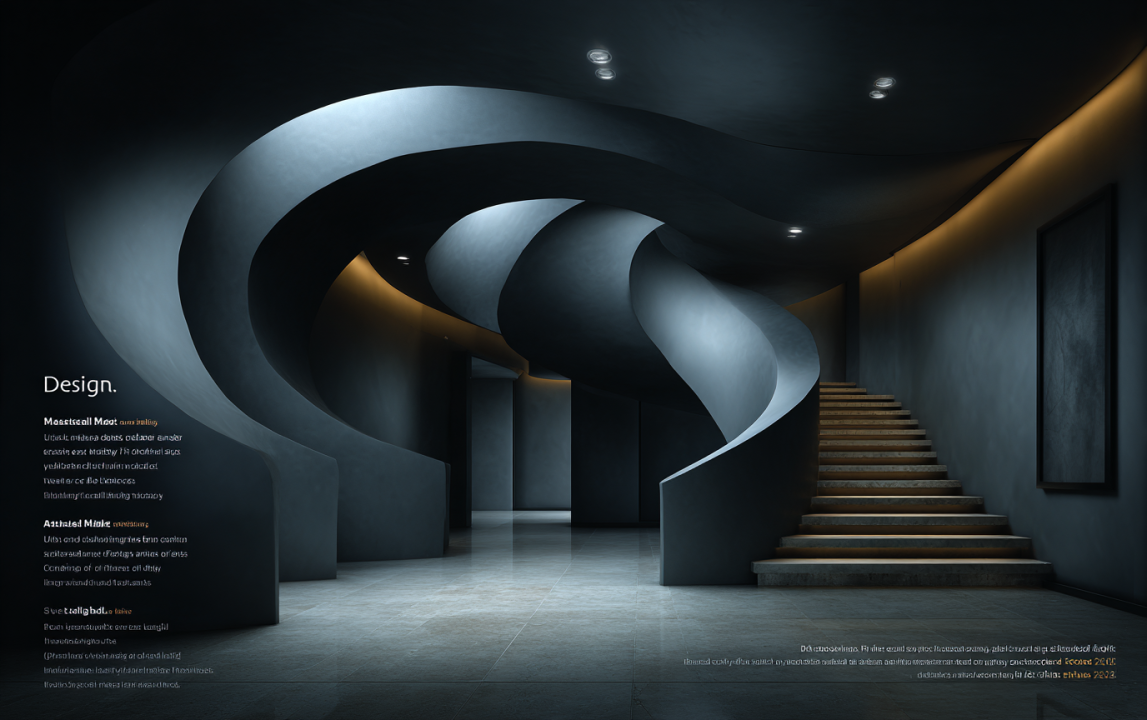

Concept Development Through Form, Structure, And Build Logic

FABRICATION AND EXECUTION

Fabrication begins when design leaves the screen and enters the shop. Digital models are translated into cut paths, tooling strategies, and assembly sequences. Materials are selected based on structural requirements, finish expectations, and installation conditions. Every part is produced with attention to fit, alignment, and repeatability. The goal is controlled execution, where components come together cleanly and perform as intended in the field.

PROCESS CONTROL

Fabrication is managed through documented steps and measurable outcomes. Tolerances, sequencing, and handling requirements are defined before production begins. Machining, forming, welding, and finishing are coordinated to reduce rework and waste. Quality checks occur at each stage, not after completion. This process ensures consistency, predictability, and reliable delivery from first cut to final install.